|

/*

* file : sonar.c

* project : Simple UltraSonic Range Finder

* author : Bruno Gavand

* compiler : mikroC V6.2

* date : september 30, 2006

*

* description :

* This is a basic ultrasonic range finder, from 30 to 200 centimeters

*

* target device :

* PIC16F877A with 8 Mhz crystal

* or any PIC with at least one ADC and PWM channel

*

* configuration bits :

* HS clock

* no watchdog

* no power up timer

* no brown out

* LVP disabled

* data EE protect disabled

* ICD disabled

*

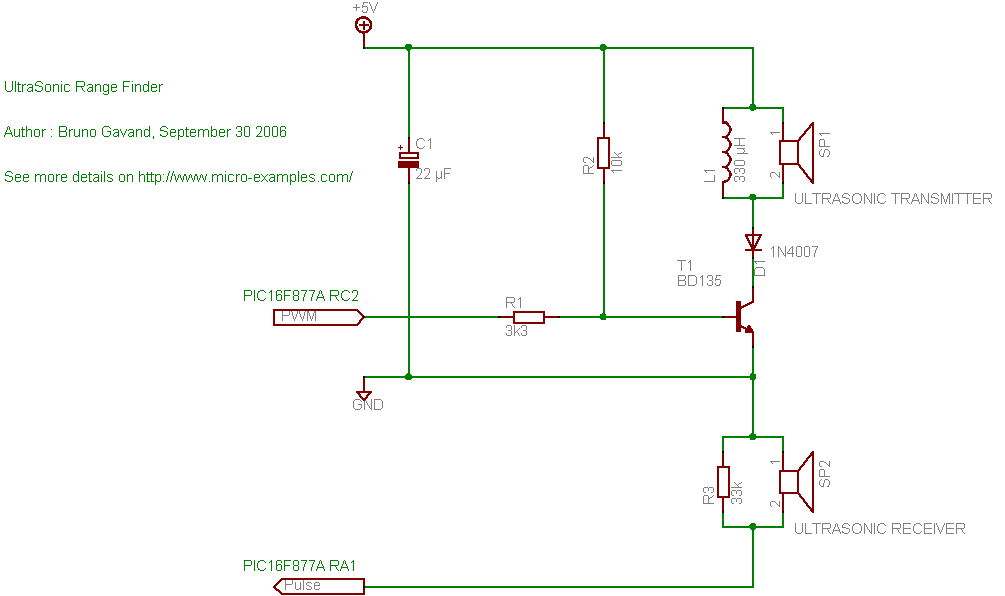

* see more details and schematic on http://www.micro-examples.com/

*/

/********************

* MACRO DEFINITIONS

********************/

/*

* ultra sonic pulse length in microseconds

*/

#define PULSELEN 300

/*

* circular buffer size for samples averaging

*/

#define BUFSIZE 10

/*

* LCD PORT

* EasyPic2, EasyPic3 : PORTB

* EaspyPic4 : PORTD

*/

#define LCDPORT PORTD

#define LCDTRIS TRISD

/*******************

* GLOBAL VARIABLES

*******************/

unsigned char outOfRange ; // out of range flag : set when no echo is detected

unsigned int buf[BUFSIZE] ; // samples buffer

unsigned char idx = 0 ; // index of current sample in buffer

/*****************************************

* INTERRUPT SERVICE ROUTINE

* This ISR handles TIMER1 overflow only

*****************************************/

void interrupt(void)

{

if(PIR1.TMR1IF) // timer1 overflow ?

{

outOfRange = 1 ; // set out of range flag

PIR1.TMR1IF = 0 ; // clear interrupt flag

}

}

/************

* MAIN LOOP

************/

void main()

{

ADCON1 = 0 ; // enables ADC

TRISA = 0xff ; // PORTA as inputs

PORTA = 0 ;

TRISC = 0 ; // PORTC as outputs

PORTC = 0 ;

// TIMER1 settings

T1CON = 0b00001100 ; // prescaler 1:1, osc. enabled, not sync, internal clk, stopped

#ifdef LCDPORT

// init LCD

Lcd_Init(&LCDPORT) ; // use EP2/3/4 settings

Lcd_Cmd(Lcd_CLEAR) ; // clear display

Lcd_Cmd(Lcd_CURSOR_OFF) ; // cursor off

Lcd_Out(1, 1, "UltraSonicRanger") ;

Lcd_Out(2, 5, "cm") ;

#endif

// init PWM Channel : 40 Khz, 50% duty cycle

PWM1_Init(40000) ;

PWM1_Change_Duty(128) ;

INTCON.GIE = 1 ; // enable global interrupts

INTCON.PEIE = 1 ; // enable peripheral interrupts

PIE1.TMR1IE = 0 ; // disable timer 1 interrupt

PIR1.TMR1IF = 0 ; // clear timer 1 interrupt flag

// forever

for(;;)

{

unsigned char i ; // general purpose byte

unsigned long cm ; // distance in centimeters

unsigned char str[4] ; // string for range display

// prepare timer

T1CON.TMR1ON = 0 ; // stop timer

outOfRange = 0 ; // reset out of range flag

TMR1H = 0 ; // clear timer1

TMR1L = 0 ;

T1CON.TMR1ON = 1 ; // start timer 1

PIE1.TMR1IE = 1 ; // enable timer 1 interrupts on overflow

// send pulse

PWM1_Start() ; // enable PWM output : transducer is pulsed at ultrasonic frequency

Delay_us(PULSELEN) ; // during PULSELEN microseconds

PWM1_Stop() ; // stop PWM

Delay_us(PULSELEN * 2) ; // do nothing for twice the pulse length duration to prevent false start

while(Adc_Read(1) < 1) // while no pulse detected (no signal on ADC channel 1)

{

if(outOfRange) break ; // to late, out of range

}

T1CON.TMR1ON = 0 ; // stop timer 1

PIE1.TMR1IE = 0 ; // disable timer 1 interrupts on overflow

#ifdef LCDPORT

if(outOfRange) // is overrange condtion detected ?

{

Lcd_Out(2, 8, "OverRange") ; // display overrange message

}

else if(TMR1H < ((PULSELEN * 6 * Clock_kHz()) / (1000 * 4 * 256))) // is underrange condition detected ?

{

Lcd_Out(2, 8, "UnderRnge") ; // display underrange message

}

else // good reading

{

buf[idx] = TMR1H ; // build a 16 bit value from timer1

buf[idx] <<= 8 ; // MSB

buf[idx] += TMR1L ; // LSB

// circular buffer

idx++ ; // next location

if(idx == BUFSIZE) // the end is reached ?

{

idx = 0 ; // back to start

}

cm = 0 ; // prepare centimeter averaging

for(i = 0 ; i < BUFSIZE ; i++) // for all samples in buffer

{

cm += buf[i] ; // add to sum

}

cm /= BUFSIZE ; // average samples

/*

* cm contains now the number of clock cycles

* from the start of the ultrasonic transmission

* to the first echo detection

* the duration in second is s = cm / (Clock_Khz() * 1000 / 4)

* if we admit that sound speed in the air is 340 m/s

* the distance in centimeters (forth and back) is d = s * 340 * 100 / 2

* or d = 340 * 100 / 2 * cm / Clock_khz() / 1000 * 4

* d = 34 * 2 / Clock_Khz()

*/

cm *= 34 * 2 ; // now converts to centimeters

cm /= Clock_Khz() ;

ByteToStr(cm, str) ; // convert to string

Lcd_Out(2, 1, str) ; // print string

Lcd_Out(2, 8, " ") ; // clear error message

}

#endif

Delay_ms(10) ; // 10 milliseconds delay before next sample

}

}

|